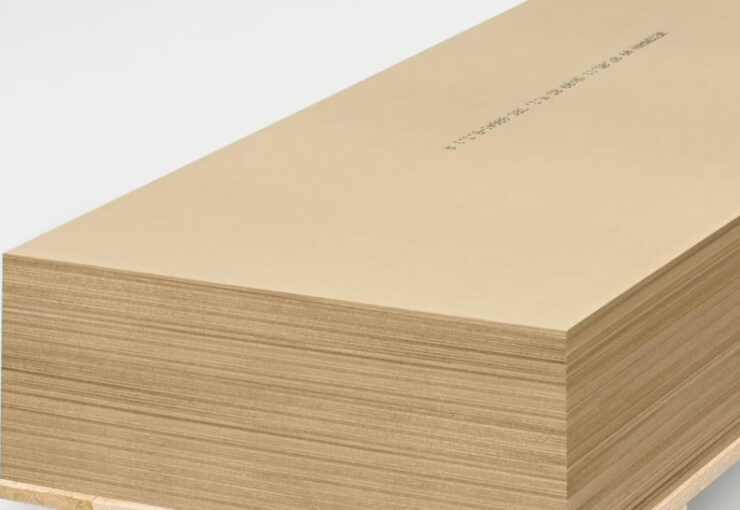

Laminated Transformerboard

Transformerboard is manufactured in accordance with IEC standards, in a single sheet and in a thickness of up to 8 mm. The thickness range can be extended up to 150 mm by laminating Transformerboard T4. In America and Europe, Weidmann uses liquid adhesives, usually polyester; however, depending on the customer specification, it may also use casein.

Since the 1940s, laminated Transformerboard has been used for clamping rings and other pressure elements, winding lead supports, end rings, and strips of S > 8 mm. It is also the base for Barrierboard and Faltenbalg rings, and therefore must meet the highest mechanical and electrical requirements. These high standards are achieved thanks to its homogeneous structure and high purity. A sophisticated and well monitored process guarantees the absence of any voids in the glue and provides a board free of partial discharge.

The nature of the material and its purity also yield long-term benefits compared to laminated wood in its environment under oil at operating temperatures. Laminated board is free of any acidic components that may affect the quality of the oil. Furthermore, the degradation of mechanical strength resulting from material ageing is also significantly delayed compared to plywood. Therefore, the higher initial purchasing cost of laminated Transformerboard is recouped in the form of a higher residual safety in the long run. This must be taken into account when considering the increased expectations regarding the service life of a transformer.