An Interview with Brad Greaves, Laboratory Service Manager

We spoke with Brad Greaves, Laboratory Services Manager at Weidmann Electrical Technology, about his role and the laboratory testing Weidmann provides, from insulation dry-out analysis to thermal aging testing, and how these capabilities translate into real-world benefits for customers.

Hi Brad, please tell us about your role at Weidmann.

Hi, my name is Brad Greaves, I’m the Laboratory Services Manager with Weidmann Electrical Technology located in St Johnsbury, Vermont.

Can you describe what the insulation dry-out analysis test involves?

When we’re doing the insulation dry-out analysis test, what we ask for is representative samples, insulation samples, to be placed with the transformer when it goes through the dry-out process. Then we would test both the moisture content and the degree of polymerization after that dry-out process to ensure that we are achieving the desired moisture content, but also not accelerating the aging of the insulation by reducing that degree of polymerization too much.

Polymer testing Rapperswil

How does this testing help you optimize the dry-out process and control insulation aging?

By doing this testing, one thing you can do is optimize the dry-out process to ensure that you are achieving that moisture content but also not accelerating the aging. You can further optimize and may possibly reduce the drying times by utilizing this analysis. Thermal aging testing is done following the IEEE C57.100 standard.

What is thermal aging testing, and how do you perform it in your lab?

We perform the sealed-tube accelerated aging testing where we place specific ratios of insulating paper, insulating pressboard, and liquid into these vessels. Those are then placed into air ovens for an extended period of time at an elevated temperature. Over time, these vessels are removed from the oven, opened, and the solid material properties are tested – particularly tensile strength and degree of polymerization. As these vessels are removed from various ovens at different temperatures, we can see how the material degrades over time and ultimately calculate the thermal class of that insulation system.

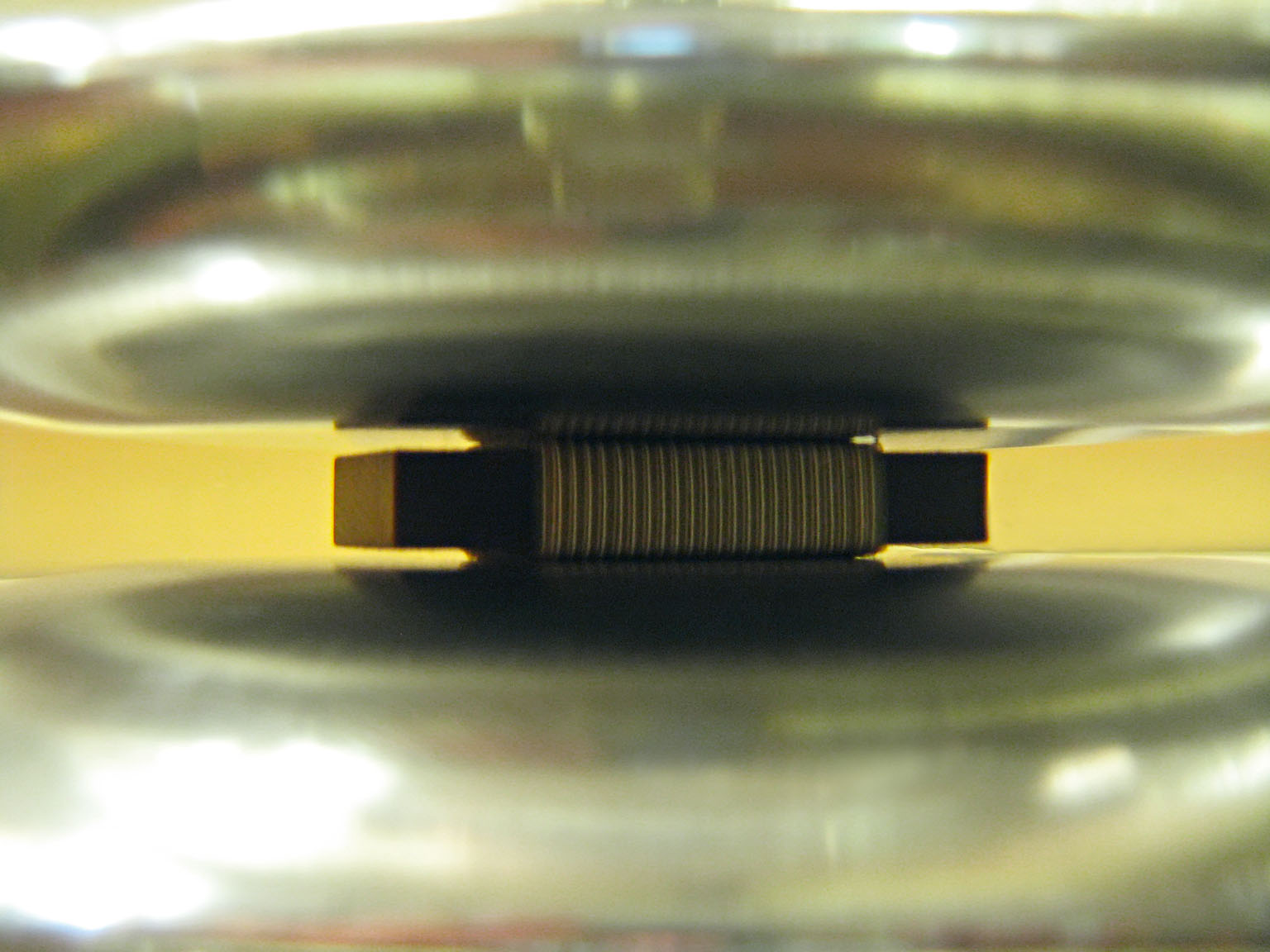

Board in oil testing close-up

How can customers use the results of these tests to improve transformer performance or design?

The customer can use this information to, one, possibly have confidence in that new material, that it’s going to perform as expected over the extended life of the transformer. Or a possible benefit could be to confirm an elevated thermal class, which can then be utilized by the transformer OEM to either achieve a smaller transformer with the same power output or be utilized to confirm a higher thermal class than an industry-proven system. We are continually investing in laboratory equipment to ensure that we can perform the tests as required. One of the recent investments at this location is a 120 kV AC transformer, allowing complete AC dielectric tests.

Visit our webinars page to learn more about the science of transformer insulation