Insulation Related Services

Expert transformer insulation

design and engineering

Weidmann offers assistance worldwide in transformer design, insulation, and other high-voltage equipment. With vast and varied backgrounds in energy-related fields, our experts provide consulting services and operational support for many different transformer applications.

Using our end-to-end support processes, Weidmann’s transformer insulation services provide best-fit solutions for enhanced transformer performance to maximize the safe and efficient delivery of electric power. Our highly skilled engineers support your transformer consulting needs with a focus on reduced budgets, increased reliability and efficiency, environmental factors, and new materials.

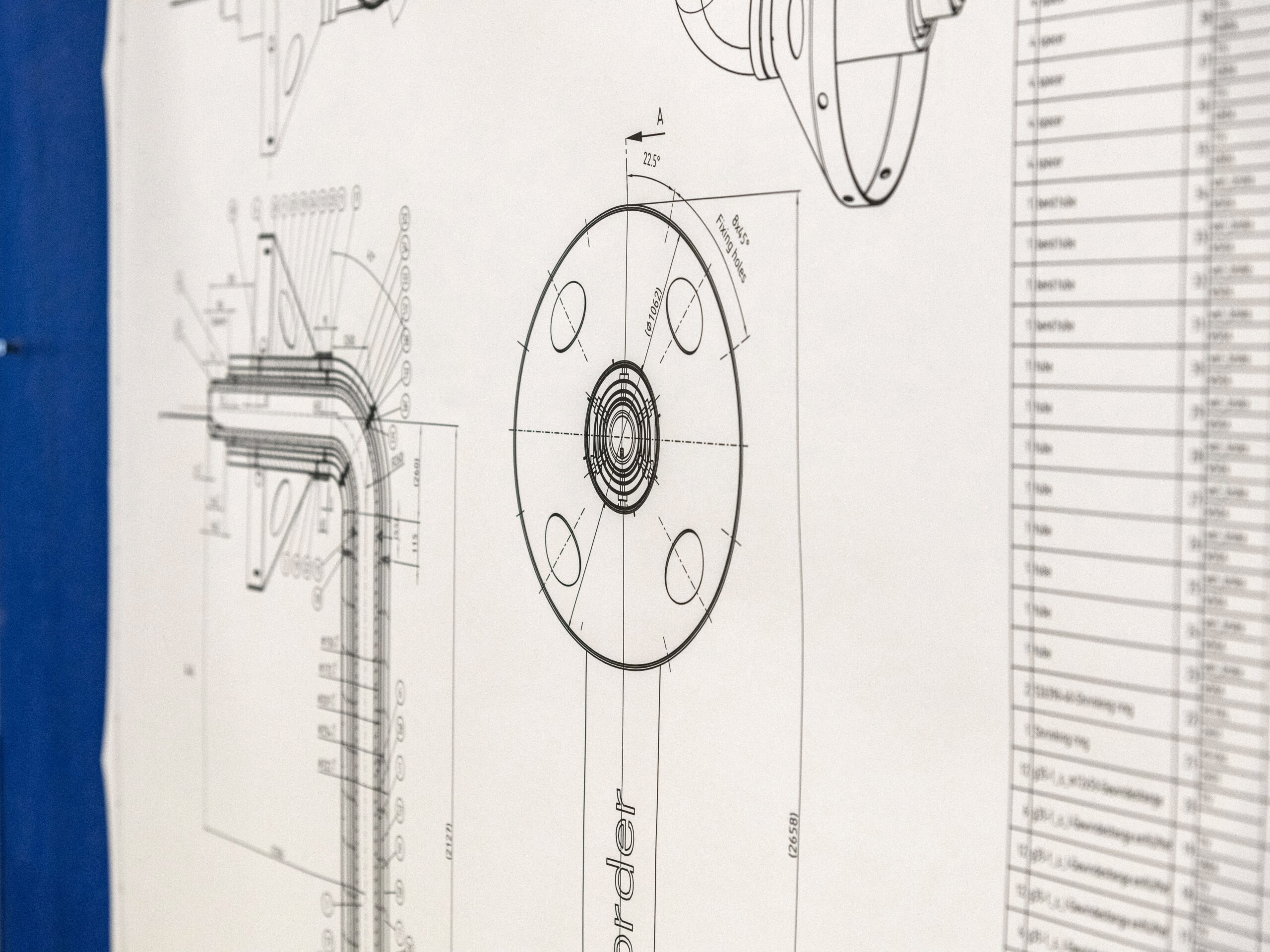

Insulation

engineering design

Weidmann’s expert engineers assist you in the insulation of power transformers and other high-voltage equipment. As specialists in AC and DC lead exit designs, we continually optimize insulation designs for your products. We can use our experience and knowledge to solve and analyze transients and polarity reversal fields for DC applications.

Mechanical tests

Weidmann’s mechanical tests are performed on materials to international standards, to ensure mechanical strength, flexibility, and suitability for transformer applications – crucial for transformer longevity and reliability. Our mechanical tests include tensile and bending strength, compression strength and compressive characteristics of materials, and air permeability and surface finish.

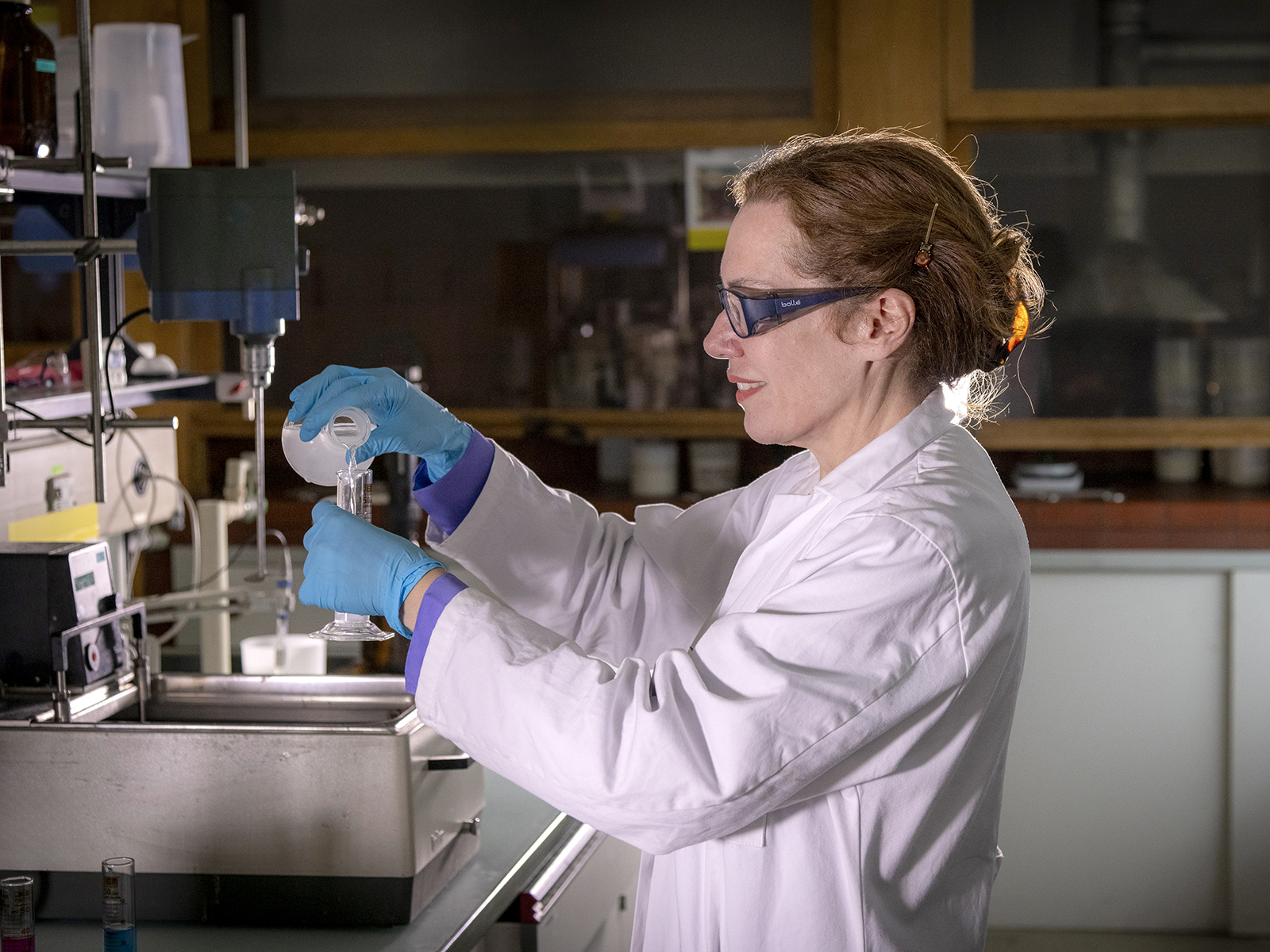

Chemical tests

Chemical tests are essential to evaluate the chemical properties and resistance of the materials used in transformers to ensure they can withstand the environmental factors and chemicals, affecting performance and lifespan. Weidmann’s chemical tests include degree of polymerization (DP) of cellulose, moisture content, nitrogen content, and pH and conductivity of aqueous extracts.

Optical tests

Weidmann’s optical tests assess the visual and optical properties of the material to provide valuable information about material quality and potential defects that may affect its performance. These tests include particles in transformer oils, particle contamination check by X-ray, and microscopy to x500.

Electrical tests

Electrical tests are crucial to evaluate the electrical properties and performance of the material, ensuring that it possesses the necessary dielectric strength, resistivity, and overall electrical integrity to withstand high voltages and electrical stresses. Tests include voltage tests, partial discharge tests, dissipation factor, conductivity and resistivity, and oil testing.

Thermal aging

Thermal aging tests are used to assess the material’s ability to withstand prolonged exposure to elevated temperatures, which stimulates the aging process that occurs during the transformer’s operation. Weidmann’s thermal aging test facilities include ovens for thermal aging up to 250 °C, and aging facilities for long-term thermal aging in oil up to 180 °C.

Extended services

Expert internal and third-party engineering support for transformer insulation systems focusing on operational reliability, network efficiency, and asset longevity. Our services include diagnostics, performance optimization, failure analysis, and tailored insulation solutions, ensuring transformers operate safely and efficiently.