Transformer Related Services

Optimum solutions for

enhanced transformer performance

Weidmann is the right partner to support your organization in a highly competitive market where manufacturing or operating a transformer is uniquely challenging. Our highly skilled engineers support your transformer consulting needs with a focus on reduced budgets, increased reliability and efficiency, environmental factors, and new materials.

DFMEA and FMEA

for transformers

Combining the expertise of our engineering and product development teams, we can help identify potential failure modes in design and assess the effects on product performance and reliability. Our process includes identifying failure modes; assessing severity, occurrence, and detection; assigning risk priority, mitigation, and prevention measures; documentation; and tracking.

Transformer

design review

Using our end-to-end support processes, Weidmann’s consulting services assist you in developing the best-fit solutions for enhanced transformer performance to maximize the safe and efficient delivery of electric power. Our skilled engineers review customer-provided technical specifications for electrical and mechanical designs, production, and drying processes.

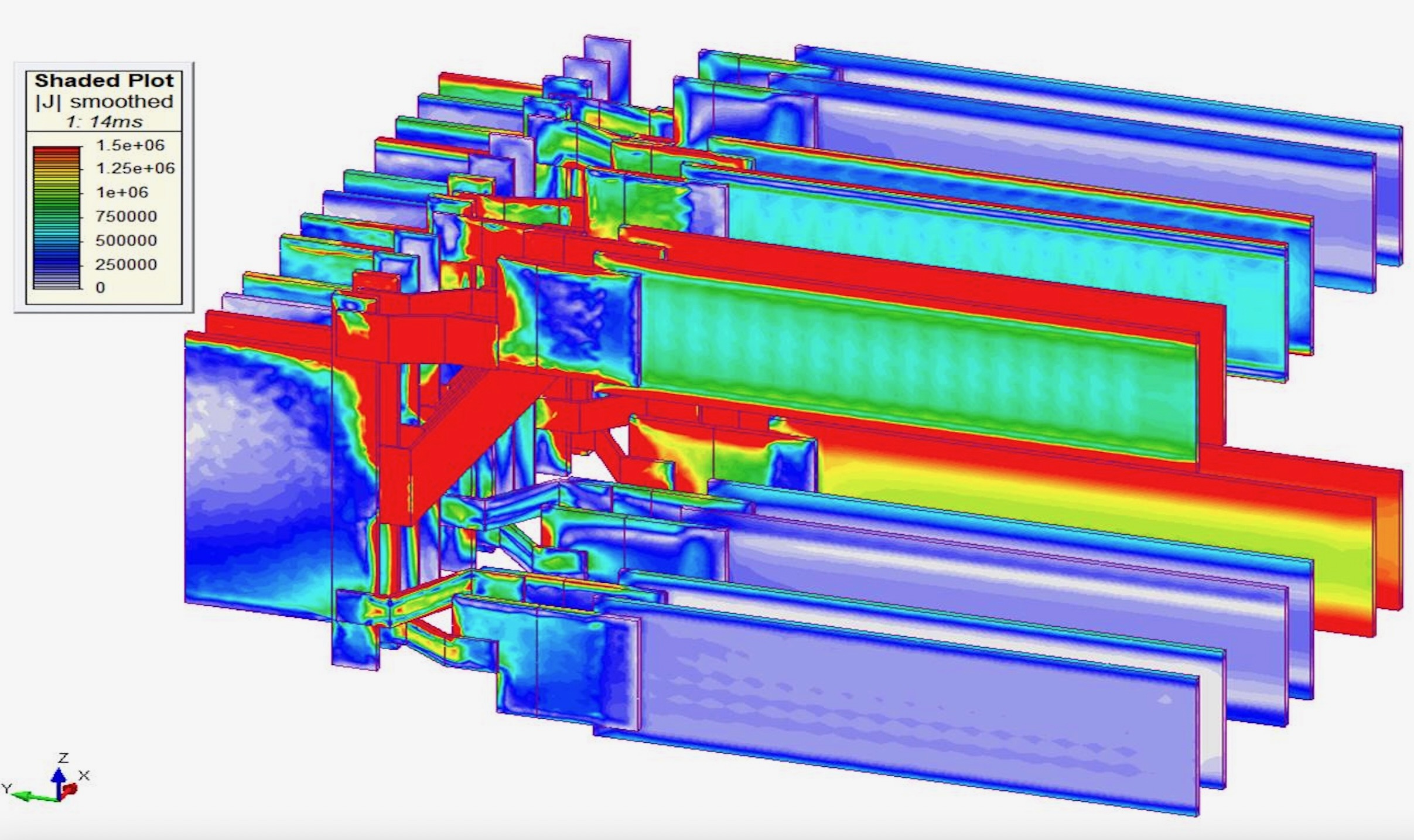

Electromagnetic

thermal studies

Weidmann offers a wide range of 2D and 3D calculations and investigations to support the design process. Using the latest technology, our engineers can calculate losses and impedances, short circuit forces, and current distributions on windings; 3D analysis of electro-magnetic shields; and 3D temperature distribution on tanks and/or clamping structures.

Transient

voltage analysis

Weidmann assists with the analysis of the voltage distribution through the windings and checks for insulation failure due to electrical stress. Our analysis helps ensure the insulation system is adequately designed to withstand transient overvoltage stresses, identifies where reinforced insulation is needed, and ensures compliance with IEC/IEEE standards.

Transformer specification review

Our experts will review customer-provided specifications and recommend revisions and/or updates to best satisfy customer needs. This scope of work includes assessing the rated voltage and insulation levels, dielectric studies, transient voltage analysis, design of the windings and voltage distribution, testing, materials, documentation, and compliance.

Bid evaluations

Our engineers will review and compare bids to technical requirements, categorize bids, and send their recommendations. Our experts will conduct a technical assessment of the bid to ensure the specified insulation meets the required performance and reliability standards, maintains the dielectric integrity of the transformer, and complies with the specifications, standards, and system requirements.

Transformer

failure inspection

Weidmann provides forensic analysis and offers services to witness the removal of failed transformers, document evidence of damage, and offer opinions regarding the cause of failure. Our experts will assist with tracing the failure back to a root cause, whether it was electrical, thermal, mechanical, or environmental.

Transformer factory

audit and evaluation

Weidmann is your ideal partner for transformer services, including condition evaluation using historical data, plant capability and process reviews, QA and testing assessments, procurement policy analysis, and support with transformer qualification. We also advise on layout and efficiency improvements and review lab reports such as DGA and liquid quality data.

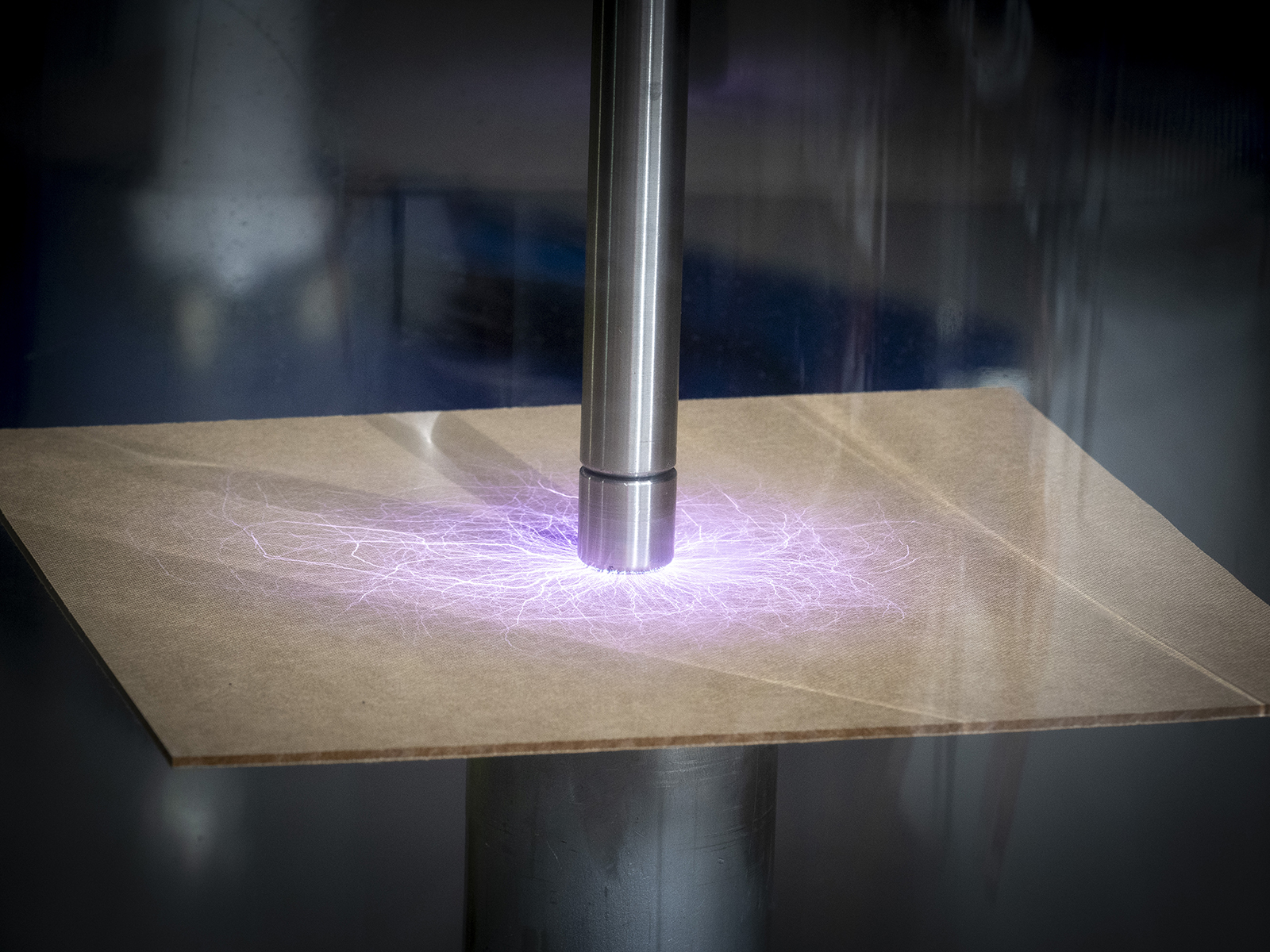

Factory test witness

Weidmann will act as the customer representative to witness factory acceptance testing. These tests are essential to validate material quality, electrical insulation strength, and the absence of partial discharges or defects that could lead to premature failure.

Third-party advisor

Our expert engineers provide technical support related to transformer design issues and insulation design. We act as an independent technical authority to ensure the insulation system is safe, reliable, standards-compliant, and suitable for the intended application.

End-of-life

insulation assessment

We evaluate the health and remaining lifespan of the insulation system to determine whether the transformer can continue to operate reliably or whether it should be refurbished or retired. We offer insulation assessment (moisture, DP, clamping) of transformers taken out of service, before being scrapped.