Technical Services for Transformers: Behind the Scenes

How can you be sure the transformer design will perform reliably under real-world stresses before it leaves the factory?

This behind-the-scenes look uncovers how Weidmann’s technical services for transformers deliver added value through meticulous insulation design analysis, comprehensive insulation dry-out process analysis tests, and expert transformer technical consulting.

From conducting DFMEA and FMEA for transformers to performing comprehensive transformer design reviews and electromagnetic-thermal studies, these services help manufacturers optimize performance, enhance reliability, and mitigate risk throughout the transformer lifecycle.

Analysis of solid-liquid insulation systems

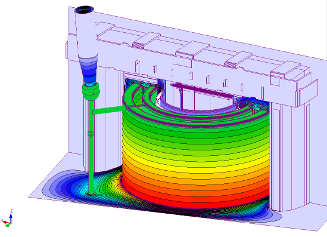

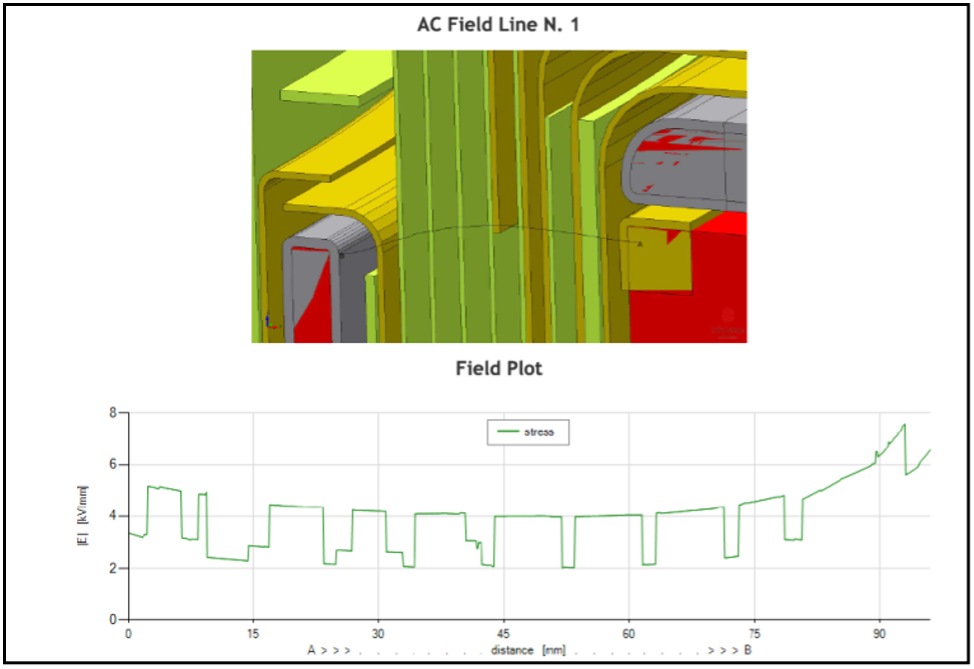

Insulation dielectric analyses are comprehensive finite element method studies of the arrangement of solid and liquid insulation components in relation to the active components.

Weidmann either creates a model based on the customer’s inputs or adapts the models created by the customer. We then load the models into our proprietary pre-processing software to simulate dielectric stresses throughout the transformer. This simulation allows us to interpret the dielectric stresses and determine how to best optimize the customer’s designs.

Insulation dielectric analyses can be used to optimize electrode-to-electrode clearances, to improve the quality of a transformer’s insulation system, and to develop new products.

Insulation dry-out process analysis tests

Insulation dry-out process analysis is used to confirm that the transformer dry-out process is removing the necessary moisture from the insulation structure while not prematurely aging the insulation.

Testing involves adding representative samples (or ‘coupons’) to the transformer that will be subjected to the dry-out process along with the transformer. These coupons will be tested for both moisture content and degree of polymerization to measure the remaining moisture in the cellulose, as well as any aging of the cellulose during the dry-out process.

A better understanding of the transformer dry-out process can help to provide confidence that the process is performing as expected and achieving the required level of moisture content. Additionally, by combining an insulation dry-out process analysis with an optimization strategy, the dry-out process may reduce overall drying time and/or premature aging of the insulation.

Insulation system thermal aging tests

Insulation system thermal aging testing is used to establish, or often confirm, the thermal class of an insulation system. IEEE C57.100 (2022) outlines how to perform this testing and complete the analysis using a known insulation system as a reference point.

Thermal aging is completed using the sealed tube accelerated aging methodology. Two-liter stainless steel vessels are filled with a specific ratio of thermally upgraded paper, high-density pressboard, and an insulating liquid, which is then thermally aged at a temperature well exceeding the normal operating temperature of the system.

As the material ages, vessels are removed from the oven, and the properties of the paper are tested (typically tensile strength and degree of polymerization) to evaluate how they degrade over time. By completing this process at multiple temperatures, the thermal index and thermal class of the insulation system can be determined.

Knowing the thermal class of an insulation system can benefit the transformer owner in multiple ways. First, confirming that a new material has the same thermal class as the industry-proven system provides a level of confidence that it will have long-term reliability. Second, if an insulation system has a higher thermal class than the industry-proven system, it allows for some flexibility for the user.

Possibly a higher-rated transformer of the same physical size by allowing a higher operating temperature, which could lead to greater reliability during normal operation, less aging over the transformer’s lifespan, or even increased short-term overload capacity without affecting the overall lifespan of the transformer.

Transformer Technical Consulting – integrated design validation using advanced simulation and risk analysis tools

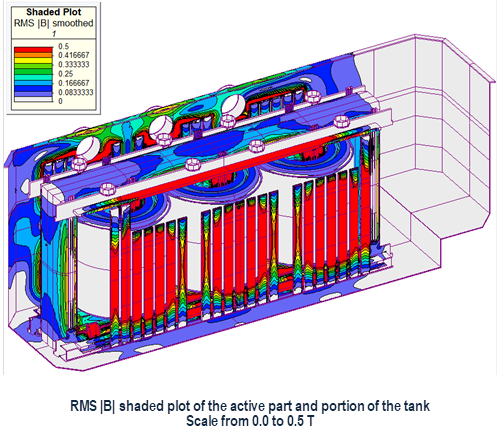

A modern and highly accurate approach to verifying transformer design and manufacturing is applied through state-of-the-art methodologies. Using established procedures such as Design and Process Failure Mode and Effects Analysis (DFMEA) and Failure Mode and Effects Analysis (FMEA), along with advanced numerical tools—including electromagnetic, dielectric, thermal, and computational fluid dynamics simulations based on finite element analysis—the entire lifecycle of a transformer, from initial design to factory acceptance testing, is rigorously assessed.

The team includes skilled and experienced electrical and mechanical engineers with deep expertise in transformers and related equipment, including power, grid, offshore, industrial, rectifier, arc-furnace, and shunt reactor units. In today’s competitive environment—marked by rising market demands, limited technical resources, and a generational shift away from electrical engineering—this expertise provides valuable support to customers striving to maintain their competitiveness.

Customers include not only OEMs and transformer manufacturers, but also end users such as Engineering, Procurement, and Construction (EPC), Engineering, Procurement, Construction, and Installation (EPCI) companies, Transmission System Operator (TSO), and Distribution System Operator (DSO). Through close collaboration with both ends of the value chain, the company plays an integral role in the development and reliability of both brownfield and green energy infrastructure.

Comprehensive and state-of-the-art transformer technical consulting services are available to support the verification and optimization of transformer design and manufacturing processes. This includes the integration of advanced methodologies such as DFMEA and FMEA, alongside powerful simulation tools—electromagnetic, dielectric, thermal, and Computational Fluid Dynamics (CFD) models based on Finite Element Analysis (FEA). These resources are applied across every phase of development, from early design proposals through to Factory Acceptance Testing (FAT).