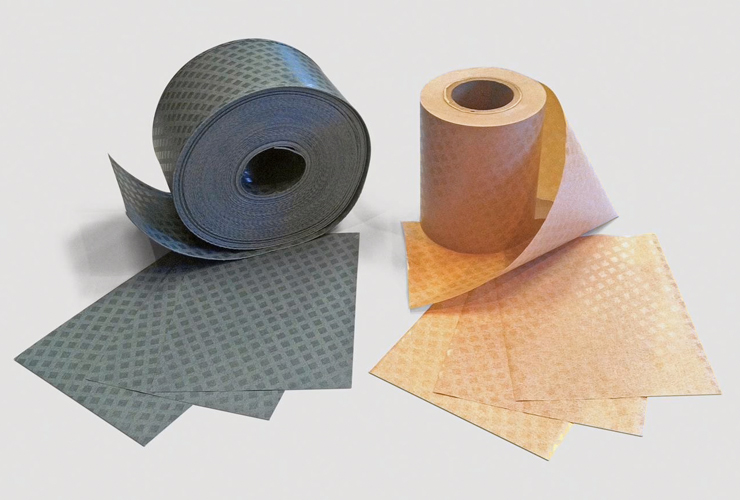

Kraft Flat Paper

About Kraft Flat Paper

Weidmann’s kraft flat insulation papers are produced in a range of thicknesses from 0.035 mm to 0.500 mm and offer the highest degree of purity and strength.

Made from 100 % electrical grade (E-grade) unbleached sulfate (kraft) wood pulp. The designation E-grade indicates a high level of purity and results in superior reliability and long-term performance under in-service conditions.

All Weidmann papers are manufactured to provide excellent electrical properties. Using only the finest raw materials, together with specially designed fiber treatment production processes, Weidmann guarantees the highest degree of purity, strength, and dielectric performance.

Thermally Upgraded (TU) papers from Weidmann, such as LD TU, MD TU and HD TU are chemically modified to reduce the rate at which the paper decomposes during thermal aging. Compared to conventional 105 °C thermal class plain kraft papers, Weidmann TU papers offer the possibility to reduce transformer size and weight, and consequently reduce transformer cost due to increased thermal capability.

Key Specifications

Presspaper range

Kraft insulating paper range

Presspaper P.4.1A is made of 100% sulfate wood pulp. It is a high-strength paper with excellent electrical properties. It is ideal for a broad range of applications. It can be dyed to various colors achievable with an unbleached furnish. Dyeing does not affect quality.

Presspaper P.4.1A TU is made of sulfate wood pulp and is used mainly as a layer insulating paper in low-voltage and high-voltage transformers. Thermally upgraded paper is a cellulose-based paper that has been chemically modified to reduce the rate at which the paper decomposes. This paper retains a much higher tensile and bursting strength than untreated papers when exposed to elevated temperatures.

Presspaper P.2.1A is a high density paper manufactured to international standards and offers the highest degree of purity, strength and dielectric performance.

Presspaper P.4.3 is made from a mixture of sulfate wood pulp and cotton. It is a flexible paper that conforms easily to uneven surfaces. Favored by coil winders, it has excellent edge folding (cuffing) properties. The paper has an optimum combination of electrical and mechanical strength, low permittivity, maximum oil absorption, minimized drying times, and maximum aging properties.

Laminated Paper 180PALU20 is offered in 25mm and 52mm aluminum stripes and is predominantly used for electric motor slots and field coil insulation.

Insulation Paper LD: This low density insulation paper has a lower basis weight and density, but offers increased porosity and higher compressibility.

Insulation Paper LD TU: This low density thermally upgraded insulation paper has the same characteristics as the LD variant, but with enhanced thermal and dielectric properties.

Insulation Paper MD: This medium density insulation paper provides the flexibility of the low density papers, but has the mechanical strength of the high density grades.

Insulation Paper MD TU: This thermally-upgraded medium density insulation paper has the same properties as the standard MD grade but with the ability to withstand higher operating temperatures.

Insulation Paper HD: High density insulation paper is engineered for applications that require superior mechanical strength, dimensional stability, and high dielectric performance.

Insulation Paper HD TU: This thermally-upgraded high density grade enables higher transformer operating temperatures without premature insulation degradation.

Interested to find out more about our Kraft Flat Paper?

Related products

Frequently asked questions

Weidmann’s industry-standard kraft paper is suitable for layer insulation in distribution transformer coils, round and flat single wire insulation, oil impregnated current and instrument transformers, as well as for oil impregnated bushings.

The thermal upgrading chemicals neutralize the acids and absorb the water caused by thermal degradation of the cellulose, providing higher temperature capability and longer life.

All our presspapers are manufactured to international standards using a multi-vat cylinder machine. This method builds up a continuous web of processed fibers in uniform, homogenous layers, resulting in a pinhole-free struture that ensures excellent insulating perfomance.