Coated Paper

Advanced insulation paper solutions

In today’s highly competitive distribution transformer sector, manufacturers are challenged to meet new customer or regulatory requirements. Increased efficiency, higher temperature withstand, and smaller physical footprint, to name just a few. Weidmann’s Coated Papers offer advanced technology solutions for the demanding needs of distribution transformer manufacturers, providing products that optimize insulation system designs, entire transformer designs, and winding productivity and performance.

Key Specifications

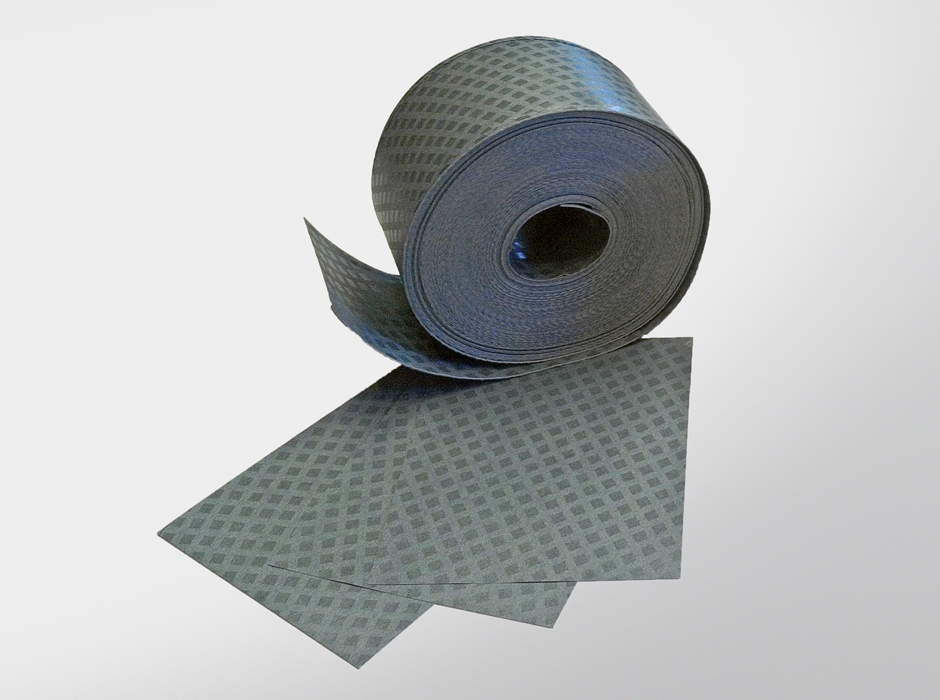

Diamond Pattern Paper (DPP)

Diamond pattern paper (DPP) improves the mechanical strength of oil-immersed transformer windings without reducing partial discharge levels. This paper is manufactured with discrete dots of B-stage resin on both sides (also available with one-sided coating) in a diamond pattern. The size and shape of the dots are carefully chosen to avoid interfering with vacuum drying and oil impregnation.

When the winding is heated for drying purposes, the adhesive dots melt and cure, thus creating permanent bonding areas unaffected by further heating cycles that may occur in service. Once cured during heating processes in the factory, the epoxy resin dots bond to the conductors and adjacent paper layers, increasing short circuit withstand strength. The diamond dot pattern also provides excellent channels for water vapor to escape during drying and fluid ingress during the dielectric fluid filling and impregnation processes.

Thermally upgraded (TU) DPP is also available, providing higher temperature capability and longer life.

INSULutions DPE

INSULutions DPE (Diamond Printed Enhanced) is a 100% cellulose insulating paper engineered to exceed the performance of traditional kraft papers used for layer insulation in liquid-immersed transformers in the distribution sector.

The enhanced material characteristics include increased thermal rating, accelerated drying and liquid impregnation rates, and better dielectric performance with excellent mechanical strength. INSULutions DPE is considered a cost-effective option for insulation in standard and higher thermal rating liquid-immersed transformers, both in mineral oil and ester liquid.

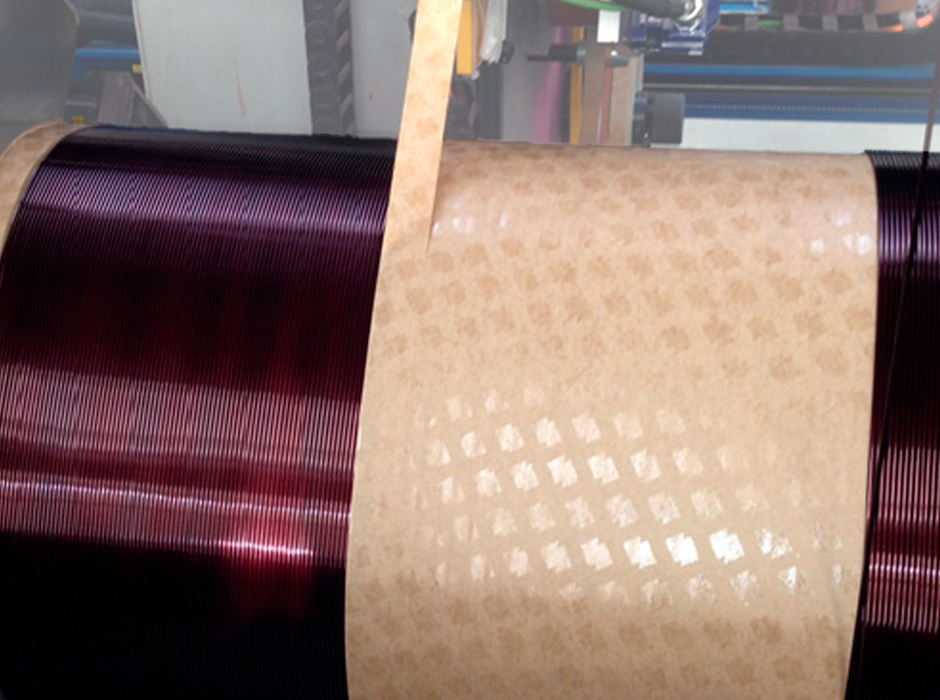

INSULutions STRIP-Flex K

Designed specifically for use on HV strip winding machines, INSULutions STRIP-Flex K provides the very best winding performance. This high-performance kraft paper is engineered for optimum winding performance, with the ability to run at high speeds and high tension.

Developed by Weidmann engineers specifically for use on modern HV strip winding machines, INSULutions STRIP-Flex K gives distribution transformer manufacturers an unparalleled level of winding performance and the ability to run at high speeds and high tension to maximize winding productivity.

TUF-Flex

TUF-Flex thin diamond-patterned coated insulation paper is ideal for layer insulation in distribution transformers. The thinness of TUF-Flex results in a smaller, lighter, and less expensive coil with lower losses and increased efficiency.

TUF-Flex insulation material is specifically engineered to withstand the stresses of winding in a transformer. Developed by Weidmann, TUF-Flex allows the distribution transformer design engineer to reduce the usage of all transformer materials and ultimately save money.

TUF-Flex’s superior mechanical properties allow thicker or multi-layer conventional papers to be replaced with this thinner, stronger grade. The use of thinner insulation allows transformer designers to reduce the mean turn length and the size of the windings, enabling the reduction of other expensive materials.

Interested to find out more about our Coated Paper?

Related products

Frequently asked questions

The coated paper is designed to bond firmly and evenly to conductor or other insulation materials with adequate time, temperature and contact pressure.

For paper stored in normal warehouse conditions, out of direct sunlight and away from direct moisture, we recommend that it be used within 12 months.

Coated paper is supplied in rolls or sheets. Rolls are wound on a 76mm (3″) core and stretch wrapped in plastic which serves as a moisture barrier.