Lead Exit Systems

Advanced lead exit systems

for high voltage applications

A critical interface between the winding and the bushing or tap changer, lead exit systems must ensure safe, shielded conductor routing through transformer tank walls—especially in high-voltage environments.

A wide range of both standard and customized lead exit systems is available, designed for use in 1- and 3-phase power transformers with AC operating voltages between 220 and 1200 kV. These systems are primarily applied in high-voltage power transformers, where mechanical strength and electrical shielding are essential.

With expertise spanning design, manufacturing, and field application, these lead exits are engineered to withstand demanding operational conditions. Their shock-resistant construction and proven ability to endure seismic events are validated in accredited testing laboratories.

Each system is tailored to meet individual customer requirements while adhering to rigorous design criteria—ensuring optimal safety, reliability, and performance in every installation.

Barrierboard

Faltenbalg

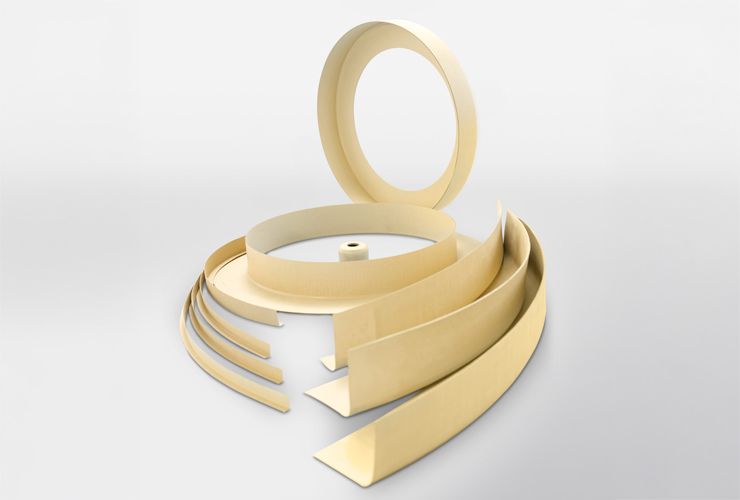

Lead Exits

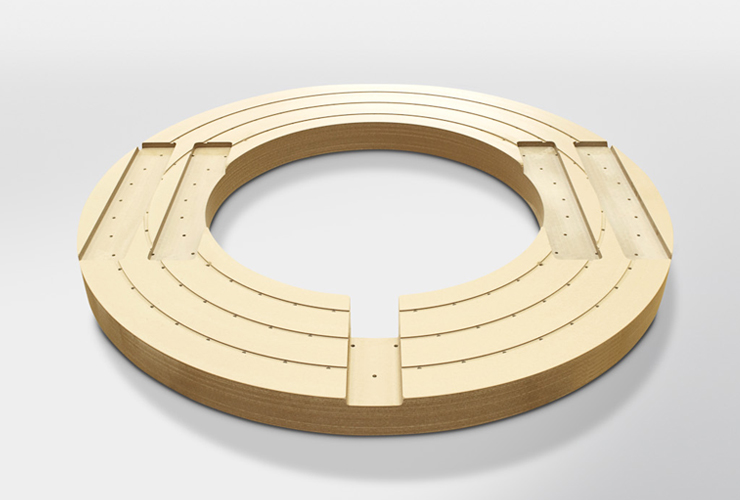

Linkboard

Lead Exits are supplied not only in a cost-efficient and reliable modular version for 400 kV or 500 kV but also in customized designs for higher voltages up to 1200 kV or even for HVDC. As a business partner, Weidmann may take responsibility not only for manufacturing but also for field studies and design. The standard design is based on a metallic core insulated with shaped Transformerboard. A number of barriers depending on the design voltage subdivide the oil gap between base insulation and tankwall. The result of our design is a minimized size of the turret at maximum safety.

Linkboard is available in several types depending on requirements. It is a customized modular insulation component for use in dual-voltage transformers. Different from the tap changing in a regulating winding, the linkboard serves as a winding connection device where the cover of the transformer tank has to be removed for handling.