Shielding Elements

Shielding components for optimized transformer performance

Shielding components are essential in transformer design, helping to reduce stray magnetic fields, minimize eddy current losses, and enhance insulation effectiveness. By mitigating electromagnetic interference, these components contribute to improved transformer efficiency, operational stability, and the extended lifespan of internal components.

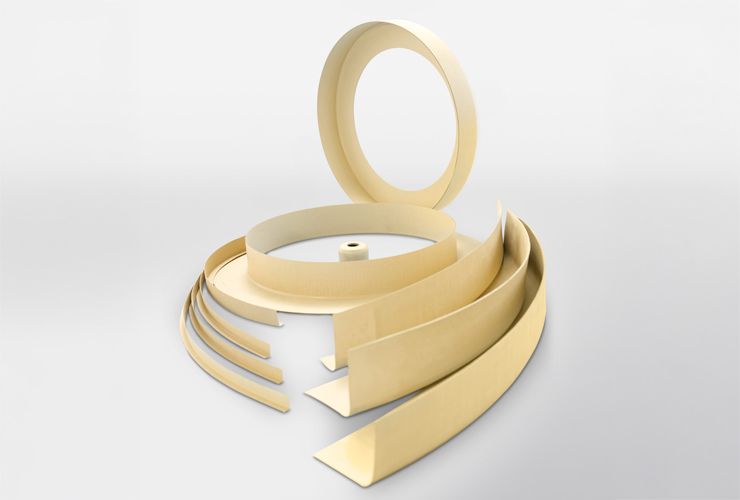

Shielding elements are strategically placed to define areas of uniform electrical potential—whether at the end of windings, around the magnetic core, or within the winding assembly itself. Flexible metalized shields provide an economical means of electrostatic shielding around magnetic cores and inside winding structures. They also allow center terminal exits through the tap winding to be shielded. Flexible shields are used in power and traction transformers. With these shields, the semi-conductive layer is bonded between two Transformerboard T4 sheets.

A wide variety of shielding solutions is available to meet diverse design and voltage requirements. These include open tapered shield rings, closed and wound metallized shield rings, as well as flexible core and yoke shields. For ultra-high voltage DC systems, some of the largest shield rings ever manufactured are also supplied to meet the most demanding performance specifications.

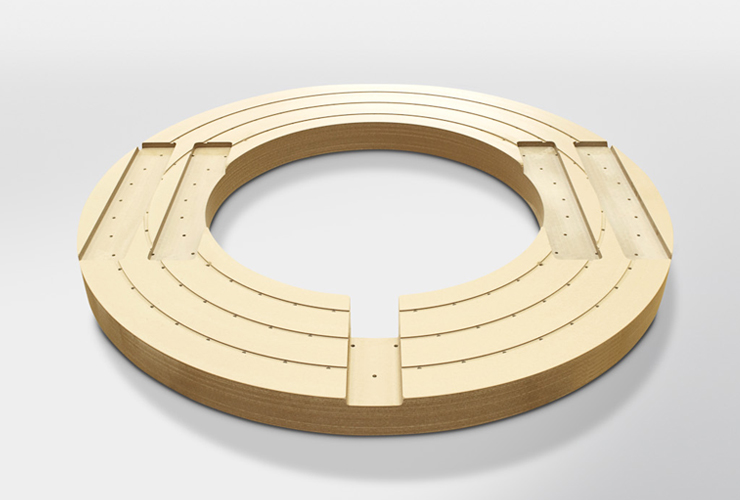

Closed, Wound Metalized Shield Rings

Open, Wound Tapered End Compensating Rings (core wound)

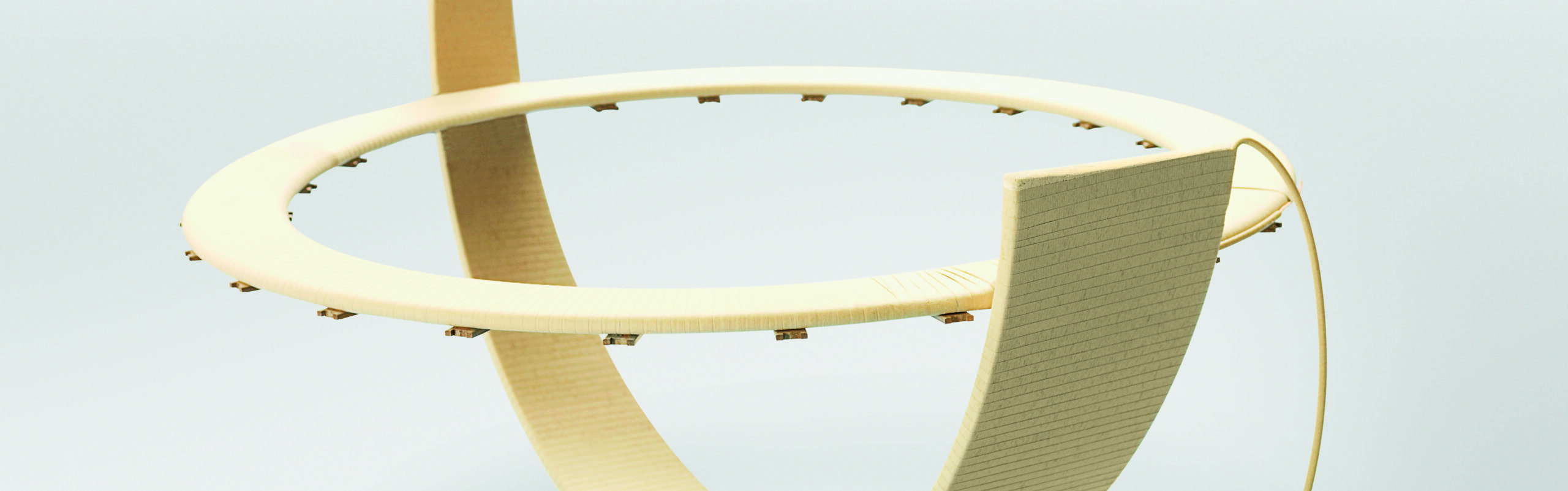

Rigid Metalized Carbon Paper Shield

Open, Wound Tapered End Compensating Rings (core wound) control and smooth the electrical field at the helical winding ends of power transformers. Wound, metalized tapered end rings are used for spiral windings (often regulating windings) to compensate for axial length.

Rigid Metalized Carbon Paper Shield is designed to be used in conditions where there is a high magnetic field, like in high voltage devices such as Series and Shunt Reactors with air gap core. The rigid cylindrical shielding comprises a metalized layer sandwiched between two cylinders. The semi-conductive carbon paper layer, connected to a copper chord, prevents local higher electromagnetic losses when exposed to the magnetic flux, typical of the reactor design.