Crepe Paper

About Crepe Paper

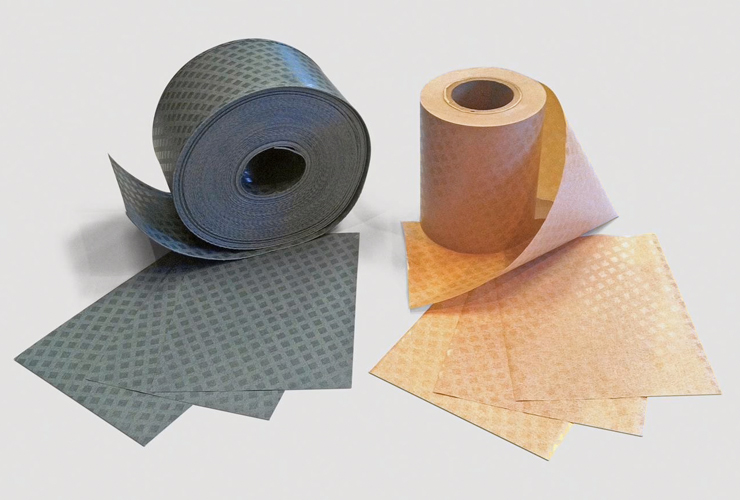

Developed in collaboration with leading electrical equipment manufacturers and produced according to international specifications, Weidmann crepe papers provide superior electrical insulation characteristics and are ideally suited to conform to irregular shapes and surfaces which cannot be achieved with flat/presspaper.

Crepe papers come in a variety of qualities developed to meet the requirements of the transformer industry. The extensibility of crepe paper facilitates wrapping irregular contours, which can be useful for joining and forming tapping leads.

Weidmann manufactures crepe papers from high-quality electrical grade kraft base papers (100% sulfate wood pulp) in reel widths up to 2500 mm. The elasticity and pliability of the base paper, combined with controlled creping process parameters, determine the properties of the final product. Careful final inspection ensures compliance with the most demanding requirements.

Key Specifications

Standard Tensile Crepe Paper

Aluminum Crepe Paper

Calendered and Super Calendered Crepe Paper

High Tensile Crepe Paper

Multilayer Crepe Paper

Semi-conductive Crepe Paper

2-way Stretch Crepe Paper

Standard Tensile Crepe Paper

This grade is usually the most cost-effective product for any application where crepe paper is needed. It is suitable and popular for manual applications in any kind of electrical equipment.

Standard Tensile Crepe Paper – calendered

This paper has additional characteristics achieved through the calendering process, which improves its mechanical strength and electrical performance. Standard grades are usually the most cost-effective products for any application requiring crepe paper. They are suitable and popular for manual applications in any kind of electrical equipment.

Aluminum Crepe Paper

This paper grade provides efficient shielding against electrostatic fields. The eddy current formation in the aluminum caused by magnetic fields is moderate. Its high elongation and flexibility allow the paper to wrap snugly and precisely around any size or shape.

Calendered Crepe Paper

Used where the application requires a tight thickness tolerance, this paper is made of standard-grade base papers and also high-density base papers.

Super Calendered Crepe Paper

This grade of crepe paper has the density of a flat/presspaper with much higher elongation, which results in high edge tear resistance and tensile energy absorption. These characteristics allow high production speeds and make these crepe grades the best choice for magnet wire insulation and applications in continuous transposed cables (CTC). Even under high mechanical stress, the high tensile energy absorption (TEA) prevents the loosening of the insulation and protects against external mechanical damage.

High Tensile Crepe Paper

This product is a strong base paper that is the basis for the production of crepe papers with the highest available tensile strength. It is the preferred product when solid insulation is required.

Multilayer Crepe Paper

This paper is constructed from multiple layers of thermally upgraded 510H crepe paper laminated together to form a superior barrier insulation in distribution transformers and is highly efficient to install.

Semi-conductive Crepe Paper

This paper insulation is used for static/shield rings and plates.

2-way Stretch Crepe Paper

This paper provides superior flexibility in applications such as lead cables, which must endure extreme radius bending, thanks to the addition of elongation in the cross-machine direction.

For more information on Crepe Paper

Related products

Frequently asked questions

Weidmann Electrical Crepe is manufactured from high quality 100% sulfate electrical grade kraft base papers. The principal mechanical advantage of crepe paper over uncreped paper is the ability to stretch in the machine (lengthwise) paper direction. The elongation or stretch allows the paper to conform to irregular shapes and surfaces.

Cellulose based paper which has been chemically modified to reduce the rate at which the paper decomposes. Because the thermal upgrading chemicals used today contain nitrogen, which is not present in Kraft pulp, the degree of chemical modification is determined by testing for the amount of nitrogen present in the treated paper. Typical values for nitrogen content of thermally upgraded papers are between 1 and 4 percent when measured in accordance with ASTM D-982.

Thermal upgrading is needed for that insulation that is exposed to the hottest part of the transformer. It is required for insulation that is in direct contact with current carrying conductors – i.e. magnet wire wrap.